Speaker

Description

Microchannel Plates (MCPs) are utilized for applications ranging from image intensifier tubes and photomultiplier tubes to mass spectrometry and electron microscopy, offering ultra-fast timing and high gain. Conventional lead-glass MCPs have been the industry standard since the 1960s. The manufacturing process includes a hydrogen firing step to reduce the lead oxide surface in the pores, bringing the MCP to target resistance and generating the electron emission layer at the same time. This functionalization limits the adjustability of the MCP for target applications.

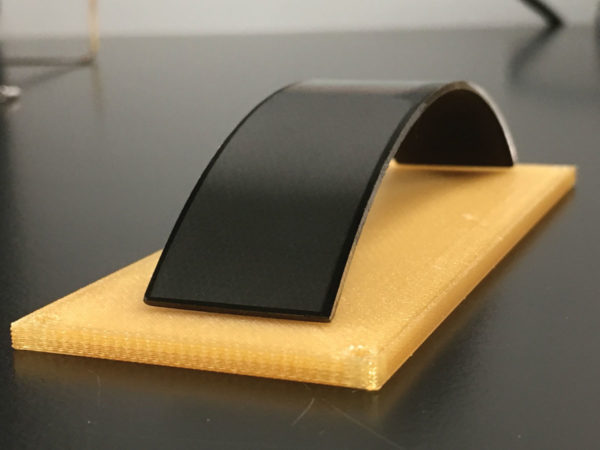

Incom, Inc. has commercialized ALD-GCA-MCP technology, applying Atomic Layer Deposition (ALD) technology from Argonne to Incom's Glass Capillary Arrays (GCAs) to produce MCPs. Incom's physically and chemically robust silicate glass allows the fabrication of large area GCAs up to 203 x 203 mm and even unconventional form factors such as curved MCPs (see image below). In addition, the high resistance of the GCAs enables functionalization with ALD, creating separate resistive and emissive layers. The tunable resistive layer defines most electrical characteristics of the MCP, serving as a strip layer to recharge the emissive layer. The emissive layer comprises a high secondary electron yield (SEY) material such as MgO or Al2O3 to provide maximum gain for intensifier applications.

Incom's 1st generation ALD-GCA-MCPs rely on the combination of Chem-1 and MgO, which provides high gain for both sealed PMTs and open MCP applications. While both the high gain and the durability of Chem1-MgO MCPs meet the standards of conventional MCPS and MCP-PMTs, further development work was needed to improve the thermal coefficient of resistance (TCR) and the after-pulse rate.

To this end, Chem5, an alternative resistive layer, was transferred from Argonne to Incom to enable the fabrication of improved ALD-GCA-MCPs that were halide free and boasted superior performance. The optimization of Chem5-MgO MCPs enabled upscaling to 108x108mm format, used in Incom’s 10 cm detector, the High Rate Picosecond Photodetector (HRPPD). The TCR of the current version of Chem5-MgO is -0.03 K-1, worse than the -0.02 K-1 achieve with Chem1-MgO. However, as a resistive coating, Chem5 revealed extraordinary current stability with over 1 mA of current measured for a chevron pair of 33 mm Chem5-MgO MCPs at 150 °C (0.8 MΩ in operation at 1 kV), exceeding the performance of both Chem1 and conventional MCPs. The high current stability reduces the risk of thermal runaway despite a higher TCR.

After-pulse rates of MCPs are related to molecules, most commonly water, adsorbed to the surface within the pores. Certain surface chemistries are more prone to this adsorption. Chem5-MgO has demonstrated high adsorption rates, but also the ability to desorb water through bakeout, yielding a more pure surface layer.

Chem5-MgO MCPs were integrated in HRPPDs to determine performance in a sealed environment. The end result was a significant improvement in gain, reducing the operational voltages from 850 V to 650 V per MCP. In 2025, Incom Inc. is transitioning the 203x203mm Large Area Picosecond Photodetector (LAPPD) to 2nd generation Chem5-MgO MCPs.